chicken bouillon cube press machine

- TP

- CN

- 40 working day

- 20sets per month

This chicken bouillon cube press machine is specially designed for cube shaped products, such as beef cubes, shrimp cubes, soup cubes,seasoning cubes and so on. And this soup bouillon cube machine is well commented by the end-users.

We can produce about 20 sets of this type of chicken bouillon cube making machine very 40 days and also the bouillon cube wrapping machines are also produced by ourself. So we can customize the whole chicken bouillon cube production line.

Just please let us know your detailed requirement about the chicken buoillon cube making machine, and we shall make the rest.

Chicken bouillon cube press machine in our workshop.

The soup bouillon cube press machine has stainless out covers, and is very easy to be cleaned. There are acrylic doors on the pressing chamber of the shrimp bouillon cube making machine.

There are two groups of pressing rollers on this chicken bouillon cube machine, and each punch can be press two pieces of chicken bouillon cubes every circle.

The thickness of the chicken bouillon cube can be adjusted in a range of 6mm, standard thickness of the chicken bouillon cube is about 10mm. And the width and length can be customized according to customer's demand.

This bucket type force feeder is designed for this bouillon cube press machine, it will jprevent the buillon material going out of the bucket type force feeder:

2Cr13 stainless die plate is applied on this seasoning cube making machine

You don't have to worry about that the die plate will be possibly scratched and damaged by mistake. And you don't have to worry about that the coating layer will be possibly mixxed into the bouillon cubes,which is possible on ordinary bouillon cube making machines, but will neven happen on our soup cube press machine, because the die plate of our seasoning cube making machine is made of 2Cr13 stainless steel and no need to be coated.

Optional automatic lubrication system details:

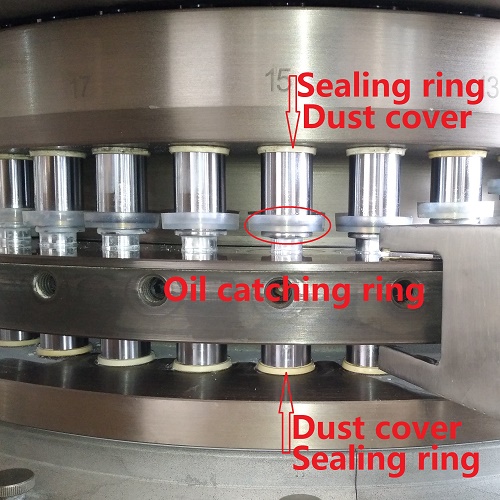

1.Dust-prevent ring:

It can prevent powder going inside the upper mold holder and oil flowing down the punch rods, reduce noise and abrasion. If without these sealer, the tablet punch rods will generate bigger noise when the punch rods moves up and down.

2.Oil catching ring:

It can catch the lubrication oil if any leaking happens, which will prevent the lurbication oil dropping onto the bouillon cube material.

3.Side fixed bolt:

Part of the bolt is in the side of the middle die, which can prevent the bolt coming off effectively.

5: Lubrication brushes for upper and lower punches

6: Pump and used oil collection system for automatically-lubrication system

Main Technical Data

Model No. | ZPTX420-19D |

Punch Dies (stations) | 19 |

Max. Pressure (kn) | 130 |

Max. Tablet Size (mm) | 35 |

Filling Depth (mm) | 22 |

Max. Tablet Thickness (mm) | 8 |

Max. rotation Speed (r/min) | 10-20 |

Max. Production Capacity (pcs/h) | 13020~65000 |

Motor Power (kw) | 7.5 |

Overall Size (mm) | 1240×980×1750 |

Weight (kg) | 1950 |

Lubrication system | Automatic |

Oil catching rings and dust cover | Yes |

Above speed is calculated according to 20r/min for reference, actual speed depends on the physical characteristics of the raw material.

Chicken bouillon cube production line was being tested in our workshop before the delivery.

Two chicken bouillon cube press machines were followed by six sets of bouillon cube wrapping machines. In fact two chicken bouillon cube making machine can feed eight sets of bouillon cube paking machines, but the customer's production area is limited so just make the layout as above.

Chicken bouillon cube production line loaded into container and was shipped to customer.